Abtrex Industries has over 50 years of rubber lining experience. Our lining capabilities include:

Rubber Lining for the Mining Industry

- Slurry Pipe

- Slurry Tanks

- Pump Boxes

- Thickener Tanks

- Flotation Cells

- Chutes and Hoppers

- Natural Rubber-Lined Tanks

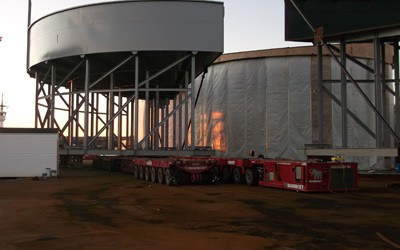

Canadian Success Story

Even Abtrex Industries’ competitors know whom to call in a pinch. Another rubber lining company called Abtrex regarding a large job they had been awarded in Canada. This company faced serious problems with completing the job in the required timeframe. 13 field-erected steel tanks needed interior rubber lining, so Abtrex Industries’ field technicians worked on-site night shifts for 8 months.

The result? Abtrex completed the job on-time and surpassed all required quality standards.

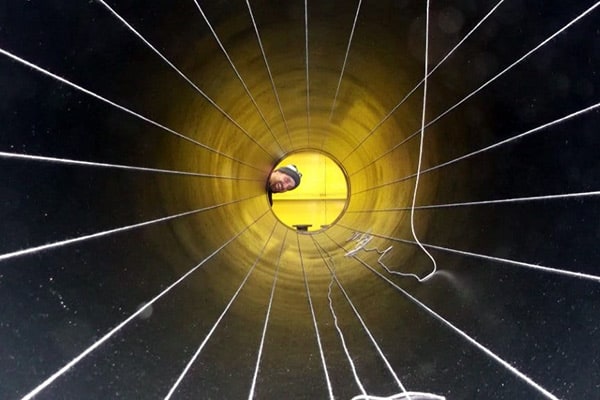

Rubber Lined Spools

In November 2012, Abtrex was hired for a rubber-lined slurry pipe job containing 386 lined spools with over 84 different configurations. The bid package contained the isometric drawings for the tailings delivery pipe. The specifications were for 386 24-inch diameter carbon steel pipes lined with ½” thick soft natural rubber. All spools were designed and built per ASME standard B31.3 Process Piping at Abtrex’ South Bend, Indiana facility.

Within a month of being awarded the contract, URS approached Abtrex asking if they could expedite the order and prioritize the spools into three categories per the installation schedule. By working two shifts around the clock, Abtrex was able to trim almost eight weeks from the original requirement. All priority one and two items were shipped before January 1, 2014.

After the pipes had been delivered, URS engineers asked Abtrex to make two additional spools, not in the original scope of work. Abtrex was able to fabricate and line these spools in less than two weeks.

Mining Products

Slurry Pipe

Piping used to transport mineral concentrate from a mine’s mineral processing plant, or to convey tailings from a mineral processing plant after the ore has been processed.

Pump Boxes

Casing or cap covering a pump.

Flotation Cells

A processing vessel used to separate minerals from slurry typically by adding a surfactant or chemicals and aerating the mixture to form bubbles. The desired minerals attach to the bubbles and rise to the top forming a froth, which is removed from the cell and produces a concentrate of the desired mineral.

Natural Rubber-Lined Tanks

A storage container for bulk material, typically one that tapers downward to allow discharge of contents at the bottom.

Chutes and Hoppers

A sloping channel or slide for discharging objects out of a hopper (see hopper definition).

Slurry Tanks

Vessel used for storing or mixing an insoluble substance such as coal with a liquid.

Neutralization Tanks

Vessels used to store, dilute and/or neutralize corrosive and chemical wastes.

Synthetic Rubber-Lined Tanks

Vessels lined with any of various products that resemble natural rubber in physical property and ability to be vulcanized. Synthetic is superior for some applications and inferior for others.

Thickener Tanks

Vessels designed for the removal of liquid from a slurry using a rake arm, agitator or other type of mixing device.

Ball Mills

A type of grinder used to grind materials into a fine powder for use in various processes. The grinder consists of a hollow shell rotating about its axis. The cylindrical shell is filled with grinding media (balls) and the size reduction is done by impact as the balls drop from near the top of the shell.

Secondary Containment

A physical barrier separate from primary containment that is designed to prevent the release of hazardous compounds.

Trommels

A rotating cylindrical or conical screen or sieve used for washing and sorting pieces of rock.

Recovery Tanks

Vessels designed and built for dilution, neutralization and/or trapping solids for disposal or recovery.

Flash Vessels

A vessel used for separating liquid-and-gas by rising the temperature or lowering the pressure on a flowing stream.